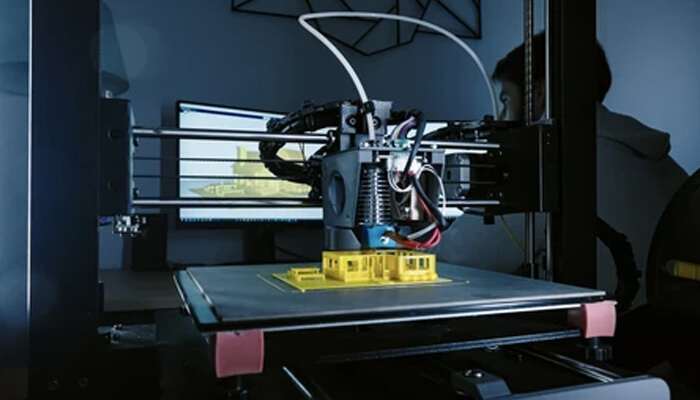

3D printing is a technology that can be used in many fields. It can be used to make prototypes, create tools and parts, and even build full-scale models. 3D printing has become a very popular way to create products because it takes less time than traditional manufacturing methods.

A 3D printer is a necessary digital technology that every business should consider using. It helps with product management, the process of defining, designing, and producing products. Products management is an essential skill for any business or organization.With a good 3D printer, your product management efforts will bear fruits and you will have a competitive edge in the modern-day digital technology field.

Factors to consider when choosing a 3D printer for your business

The key to choosing the best 3D printer for your business is understanding what you need it to do. If you’re looking to prototype or add-on products, then you’ll want something that has a high print volume. If you’re looking to create new products, then you’ll want something that can handle large objects like cars or furniture. In other words, choose what will help ensure business growth.

Here are some things that you should consider when choosing the best 3D printer for your business:

1. The type of business you run

The first step is to figure out what type of business you run. If you’re a large company with multiple locations, then it’s likely that you’ll want more than one 3D printer in each location. If not, then you may only need one or two depending on your needs.

2. Print Volume

The first thing that people think about when it comes to choosing a new printer is the size of the print volume. This is important because it tells us how much material we can realistically print in one go and how quickly we can finish projects. It also affects our storage needs and materials costs over time.

The higher the print volume on a 3D printer, the more parts or products it can produce in a single pass of its print bed. This means that there are fewer parts per model and less work required by staff members during production. High volume 3D printers can even generate prototypes before production begins so that everyone involved has an idea of what their final product will look like prior to committing resources to it.

3. Speed

This refers to how quickly your machine can print out new parts – think about how long it takes for your machine to produce a new part versus how long it takes for other machines in your production line. The speed at which your machine operates will determine how much time a single worker has available between cycles on the line, which affects efficiency and overall production rates.

4. Production Speed

Since most businesses don’t have the ability to produce large numbers of products on-demand, speed becomes an important factor when choosing a 3D printer for business purposes. You want something that can run fast enough so that any changes can be made quickly and easily in case there are any issues with the design or materials used during printing, which may cause delays in production time if it takes too long for someone else to make changes to the design before printing begins again.

5. Capacity

The bigger the capacity (in mg or grams) of each model, the less time it takes for prints to complete once they have been started. This is because larger models can hold multiple materials within their chamber while smaller models can only hold one material at a time. So, if you are not in budget, then choose a 3D printer with the capacity that will ensure good business growth.