There are many benefits to using vibration analysis in your company. From saving money on operation costs, to getting the products you need on the shelves faster, using Vibration Analysis has some really good benefits.

It is a process that allows you to identify ‘abnormalities of vibration’ in a machine or component. Some states have used its findings for legal purposes and domestic violence investigations.

What is vibration analysis?

Vibration analysis is the practice of studying the vibration characteristics of objects or systems in order to understand how they work or how they fail. This information can be used to improve design, performance, and safety.

As the name suggests, vibration analysis is the use of vibration measurements to study the behavior of structures and components subjected to mechanical stress. By understanding the vibrations that a component or structure experiences under different conditions, you can learn more about how it behaves and how best to maintain it.

The benefits of vibration analysis are many and varied, but some of the most important include:

– improved product quality and reliability

– reduced maintenance costs

– improved safety

– faster decision making

– greater insights into customer needs

How does the process work?

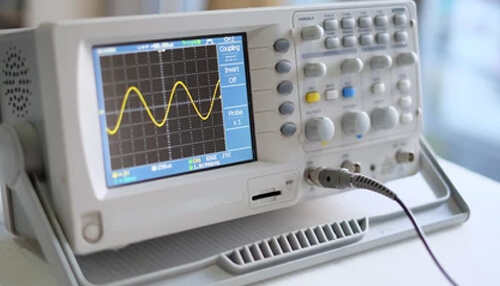

The vibration analysis process begins by gathering data from the object being analyzed. The data is captured through vibration analysis equipment, such as accelerometers, piezo-electric transducers, and magnetometers. Vibration data can be collected in real-time or recorded for later analysis.

Once the data has been collected, the analysts use a variety of software to analyze it. This includes programs that measure different types of frequencies and patterns, as well as those that help identify flaws and potential problems with the object. Ultimately, this information can be used to improve the design or performance of the object in question.

How does vibration analysis help your business?

Vibration analysis can help your business optimize its processes, reduce noise and vibration levels in the workplace, identify potential problems early, and improve safety.

Some of the benefits of vibration analysis include:

Optimizing processes – By identifying which processes are generating the most noise and vibration, your business can find ways to optimize these operations without compromising safety. This can save time and increase efficiency.

Reducing noise and vibration levels in the workplace – By reducing noise and vibration levels in the workplace, you can improve worker productivity and protect equipment from damage.

Identifying potential problems early – By monitoring noise and vibration levels often, your business can identify potential problems early and take appropriate action. This can save money and hassle down the road.

Benefits of Vibration Analysis

Vibration analysis can help organizations learn about the cause and potential effects of vibration-induced structural problems. This information can then be used to correct or prevent them. Additionally, vibration analysis can provide insights into the performance of a system or the health of its components. Here are some of the benefits of vibration analysis:

1. Reduction in Error:

By identifying and correcting problems early, vibration analysis can minimize the amount of damage that results from incorrect or incomplete work.

2. Identification of Malfunctions:

Vibration analysis can identify subsystems that are not operating as they should and can help diagnose malfunctioning equipment or mechanisms.

3. Prevention of Damage:

By understanding how a system behaves and how it is likely to behave in different environments, vibration analysis can help organizations avoid causing damage during operations. This can save both money and time.

4. Focused Management:

By understanding how a system is performing, management can better allocate resources to areas that are most important. This allows organizations to maintain critical functions while reducing overall costs.