Stepper motors are DC brushless motors that are often considered interchangeable with DC servomotors for applications that require precision. The applications that they work for range from machine tools, medical equipment, computer peripherals, and automotive devices, among many, many more. The stepper motor is the source of power for linear actuators when motion is required to be very precise and is becoming more popular than DC servomotors for a variety of reasons. In this article, we will go over some of the top reasons for choosing a stepper motor actuator over a DC servomotor.

1. Precise Positioning

The stepper motor have a high pole count that is usually between 50 to 100 that renders a position encoder unnecessary. They move in precise steps, hence the name stepper motor. Each electrical pulse is delivered to the driver in a precise pulse that sends proportional voltage to the motor.

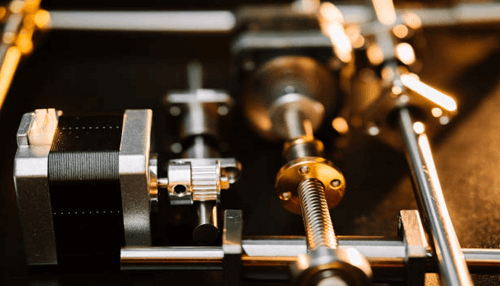

These movements in the motor are extremely accurate and don’t deviate at all. The steps are also much smaller than what happens in a DC servomotor as the only moving part is the rotor where the magnets are located. For things like 3D printers, medical equipment and CNC machines they are an excellent choice.

The only time the steps are not accurate is when there is a high electricity load used so they are best for applications where the maximum current corresponds with a low top speed of the steps.

2. Cost-effective

The costs of a stepper motor actuator are far lower for a stepper motor than most other types of drive motors. One reason for that is the low consumption of energy required for low-speed, but precise applications. There is a lot of torque produced at these low speeds that other motors can’t achieve and at a fraction of the price as well.

These motors also last a very long time and require less maintenance so the costs stay low over the lifespan of the device. Maintenance is also less invasive and costly than with some other motors.

Then there are the costs to start them going. They are easy to set up which saves on training costs to be able to learn how to use the application. They are also simple to configure and set up the systems to begin operations.

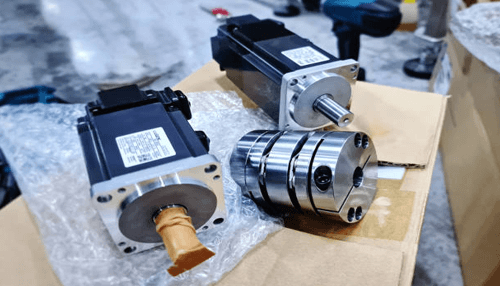

Lastly, they don’t need a lot of complex parts so their construction of them is much less expensive than other motors. This also lowers the cost to maintain, as replacement parts will be fewer and less costly.

3. Torque

Stepper motors are known for their amazing torque. In terms of speed, there is a lot of torque produced even at low speed but with very high precision. Many applications benefit from this kind of torque but it doesn’t end there.

Holding torque is also an advantage and sets a stepper motor apart. Adding to the precision is the ability of these motors to hold their torque position even when standing still. When restarted, they carry the same torque as where they left off.