Russia now has its very first 3D-printing houses which were constructed in Only 24 Hours and for Just $10,000.

The structure is only 38 square meters (about 400 square feet) and includes a kitchen, living room, and bathroom. On its website, Apis Cor claims that this is the first house to be printed on-site rather than being assembled from pre-printed pieces made at an alternate location.

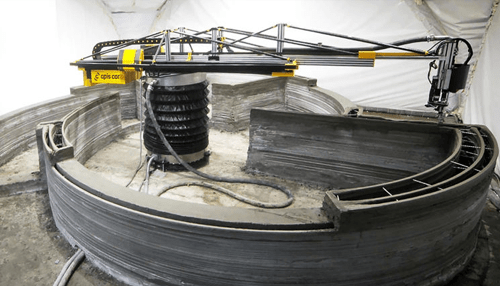

This was possible thanks to the company’s mobile 3D printer and concrete mixer, which took only about an hour to assemble. Human workers were needed to install the home’s windows and fixtures.

Prior 3D-printed structures have included an apartment building and villa in China and an office building in Dubai. Both of these projects used building sections that were at least in part printed off-site.

The design of the single-story residential house is rather unusual. This project was selected specifically, as one of the main purposes of this construction is to demonstrate the flexibility of equipment and the diversity of available forms. The house can be of any shape, including the familiar square shape, because additive technology has no restrictions on the design of new buildings, except for the laws of physics. It means it’s time to talk about the new fantastic potential of architectural solutions.

The house was erected in the coldest time of the year. Winter has added complexity to the project participants, as the use of concrete mixture, that is used as the printing, is only possible at temperatures above 5° C. Although, the equipment itself is able to operate in temperatures down to minus 35° C. The problem was solved by setting up a tent that provided the required temperature.

Soon, using new materials, such as geopolymer, you will be able to print a house at any time of the year.