The prices are rising for houses, and therefore the ability to create high-quality 3-D printing construction is an advantage.

It will be eco-friendlier and cost-effective housing to address sustainably the current housing emergency.

How 3-D printing can solve the housing crisis?

The construction industry is facing unprecedented challenges. There is a shortage of housing globally, and pushing the innovation limits is the priority. It is to implement new technologies, and promising is the 3D printing for construction.

The technology is undergoing testing in reshaping residential, apartment buildings, and houses. 3D printing is a viable alternative that is a sustainable, efficient, and cost-effective solution for housing.

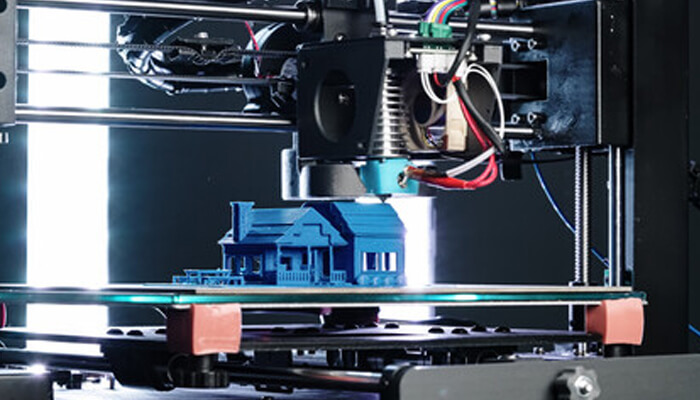

The printing process

3D refers to three-dimensional shapes created using computer-controlled processes. There is no use of formwork. A large printing machine works on cloud technology. It operates on a metallic frame with three axes and configures the direction in different applications. There is no need for soil, mortar, concrete, or other items. It is an eco-friendly, fast construction technology that contributes to creativity.

Design flexibility

It is an automated process producing repeated models. 3D printing offers high design flexibility. The changes are easy with a digital system and model that practically gets any shape or surface is possible. Rough or smooth surfaces, and straight or curved walls, offers fluid movement and structural efficiency.

The walls are double-skin, and the architects explore innovative, unique, and eye-catching buildings. There are inhabited projects built meeting stringent construction needs to suit all comfort. It demonstrates 3D construction printing as a sustainable development project featuring the potential of an affordable housing project.

Efficiency

The process of printing has the potential to augment productivity and efficiency. It offers planning reliability to high-degree, where it requires monitoring efforts and low coordination. Using standard materials such as brick or wood houses takes years or months to complete.

Fortunately, by using a 3D printer, the time of construction reduces drastically. You also get to save 60% time and 80% labor on the site, which means the financial investment required is also less. A house translating to less cost is to develop in a few days. Here the digital model will be the resulting building, an exact copy. It is like picture printing. The automated process requires no manual input and little supervision, reducing work injuries and design errors chance.

Sustainability

Energy efficiency and high resource represent sustainable development. However, it is a long way for 3D printing to become eco-friendly to 100%. The beauty is that printing hollow walls require less material. The printer minimizes concrete use by using the exact amount and brings to life the digital model. No construction water, no on-site installation, and 3D printers using cloud technology can develop structures.

The structures are using sustainable, organic, and renewable materials, such as tiny houses of mud. It can be raw earth homes or bamboo composite structures. Using fewer materials is the advantage as it generates less waste and reduces transportation needs. Printed buildings reduce carbon footprint as it potentially uses recycled or natural materials.

Address housing crisis

The global population in huge numbers lives in slums as urban households is unaffordable. With the increase in prices, the number of slum dwellers numbers will increase due to a lack of financial investment. Therefore, 3D printing is an optimistic way to address the housing crisis. It can create eco-friendlier, cost-effective, and high-quality buildings. It is a viable solution. Process efficiency does not require compromising aesthetics and creativity. There is high design flexibility with 3D printing and strikes a balance between form, beauty, and function.