Titanium and its alloys have become some of the most used metals across various industries like military and aerospace engineering. You can even find small niche goods made from titanium offered as a more premium option to regular stainless steel.

However, titanium can be notoriously hard to work with if you aren’t using the correct tools and methods. The metal has an appealing weight-to-strength ratio, making it a popular choice in high-quality goods, but also a challenging metal to machine.

As a metal manufacturer or machinist, titanium is a metal you’re sure to encounter. These jobs tend to pay well, so you don’t want to miss out. Learning to machine titanium could be incredibly advantageous for your business.

Where It’s Used

The versatility of titanium makes it a popular choice by engineers designing for a wide range of high-intensity applications. It’s got significant biocompatibility, high strength, and resists corrosion. Furthermore, it weighs slightly more than half but is significantly tougher than most grades of steel.

You can find titanium used in:

1. Medical

Biocompatibility means titanium is non-toxic and unharmful to living organisms, making it a good choice for medical tools. What you may find more interesting is that titanium is often used to make implants that go inside the body, like pacemakers, hip replacements, and even dental implants.

2. Military

Missiles, tools, artillery, protective wear, and aerospace areas benefit from titanium’s strong and lightweight properties. Lightweight tools and supplies make transportation easier, and strong tools last longer and endure heavy-duty usage.

3. Marine

Saltwater is corrosive, so titanium is often used for various components on ships and submarines, like propellors. Its weight also results in a lighter seacraft.

4. Jewelry And Other Small Items

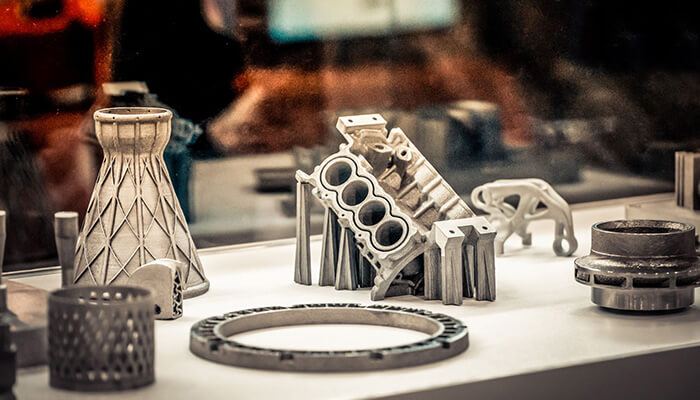

Being lightweight and tough makes titanium popular for high-end, long-lasting jewelry, like rings and watches. Additionally, small businesses might use a titanium 3D printing service to create a higher-end line of products. Examples include titanium wallets, knife handle scales, decorative beads, survival tools, flashlights, and heavy-duty carabiners.

Things To Remember When Machining Titanium

When machining titanium, you must:

1. Beware Of Heat

Heat is easily one of the most critical challenges to prepare for when machining titanium because of its low thermal conductivity. Most of the heat directs to your cutting tool. In turn, this can blunt the tool and create even more heat.

You can use a high-pressure coolant to help reduce heat. If you get the positioning right, it can help achieve a quicker, more accurate, and more efficient cut.

2. Keep Your Tools Sharp

The properties of titanium make it harder and more elastic than most other metals. Some metals, like steel, can benefit from a slightly rounded cutting edge. But not titanium.

Rounded or blunt edges only lead to more heat, which can actually cause the material to harden further. Using a sharp edge helps to keep the cutting cool, leading to a better cut.

3. Choose More Flutes

Using a tool with the right number of flutes contributes to how successful a cut will be. It typically depends on how many chips your endmill can have before it starts clogging. It’ll also depend on the shape of the part and how efficiently you can clear chips.

Titanium cutting bits are usually found with at least four flutes, but can have more than 10 in some cases. Determining the best to use in each situation isn’t always easy, but you’ll get better with experience.

4. Find The Right Tool Coating

Coatings can play a massive role in your cutting tool’s ability to handle heat before it fails. Titanium aluminum nitride (TiAN) is one of the most recommended coatings for cutting titanium. TiAN contributes to heat and oxidation resistance, which may let you cut at higher speeds.

Coated tools made from carbide, like tungsten carbide, can make good cutting tools for machining titanium.

5. Go For Secondary Relief

While you need sharp tools to cut, they are also easier to damage. Titanium cutting tools designed with secondary relief add some extra strength behind the cutting edge. Using secondary relief makes the tools stronger and longer-lasting.

6. Use Workholding

Titanium is relatively flexible and will resist cutting. Therefore, it’s essential to ensure the part is held in place firmly before you start a cut. Strong, rigid workholding is always a benefit in titanium machining.

Try to always cut against a firm stop, work on a strong, flat surface, and use grippers wherever possible.

7. Plan Your Cut

By far, one of the best things you can do in any titanium machining job is to plan cuts before execution. This will depend on the part’s geometry, the tools you have available, and the nature of the cut you need to perform.

Conclusion

Titanium machining used to feel like a complex job only offered by specific workshops, manufacturers, and machinists. But it’s not as difficult as it used to be.

Cutting titanium is about understanding the material, taking proper measures, using the right tools, and learning from experience. Know that titanium will resist cuts, will likely heat up less than your tools, and needs to be held firmly. Choose tools made of strong materials that are coated to resist heat.

Of course, you may not get it right from the start every time. But planning, practicing, and reflecting will build experience that’ll improve your cuts over time.