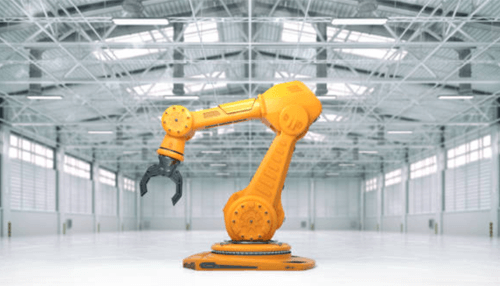

A robot arm is a programmable mechanical device that imitates the same functions as a human hand. It may be a part of a robot or maybe the complete robot platform itself.

You can also describe a robot arm as a mechanized and programmable manipulator that may serve the same function as a human hand.

They may represent a part of a robot or maybe a complete unit in itself.

A robot arm comprises rotating joints that give the robotic arm a wide range of motion which include rotation motion and linear displacement.

These robot arms consist of joints that allow rotational motion or translational displacement. A kinematic chain is said to be formed by the joints with the terminus of the kinematic chain commonly referred to as the end factor.

A robot arm has an end factor which refers to a feature that resembles a human hand that is used to pick, drop, and move items from one point to another. The end factor in this case imitates the grabbing motion or action of a human hand.

Robot arms can perform several different operations such as picking and dropping items, welding, assembly, etc.

Robot arms also have the potential to be fitted with several different end factors with the most commonly used end factor being the one that resembles a human hand.

Robot arms are controlled using a potentiometer. Each joint movement is controlled manually by the potentiometer’s shaft being attached to a motor.

A robot arm has many benefits which include the following:

Job Creation

Contrary to popular opinion, a robotic arm creates more jobs than the ones they take away.

By introducing a robot arm to your workplace, you create a job for the person who has to oversee the robot arm working. A robot arm still needs human input to function as well.

The more people need the services of a robot arm, the higher the demand for production increases which translates to more jobs for human beings who assemble and program the robotic arm.

By encouraging your workers to embrace and work together in tandem with robots, you are helping them acquire and develop new technical and engineering skills and knowledge that they otherwise did not have.

Accuracy and Precision

Robot arms are precise and accurate. Once they are programmed, they perform each programmed function with tremendous pinpoint accuracy without deviation.

Due to the accuracy of the robot arms, the final products are of high quality which translates to longevity which appeals to the customer. This leads to more sales and better profit margins for the company.

High Productivity

Assigning a robotic arm the work a human was doing can lead to increased productivity.

A robot arm can carry out the bulky and tiresome work and leave human beings with enough time to focus on innovative projects or ample time for them to respond to emails, talk with clients, and much more.

This is an advantage for any company because the robot arm is working on the production side of things and your human employees are working on the interactive side of your company. This leads to high-quality products and satisfied clients.

Consistent Speed

A robot arm does not get affected by human factors such as fatigue, stress, or stress which limits a human employee’s capacity to work and speed of work.

A robot arm is a perfect employee that needs no vacation, or off days. They can work continuously day and night without stopping leading to a faster production time.

They substitute humans for having to meet impossible deadlines, working at impossible speeds, and trying to achieve a constant product quality that is not possible for a human.

Efficient

Efficiency is important for any business to be competitive today.

Robot arms are efficient. This is one of the many things that set robot arms apart from humans.

Robot arms can be programmed to perform tasks efficiently and faster saving time and improving overall production capacity. This translates to more sales and a better market position.

Conclusion

Any company that is serious about wanting to make products of the highest quality have a constant production line to meet the demands of consumers and spend less to make more has to implement the use of robot arms.

A robot arm will save you and your company the burdens of having to ensure the safety of your employees in dangerous environments and it takes away the possibility of an accident and the risk of facing a lawsuit.